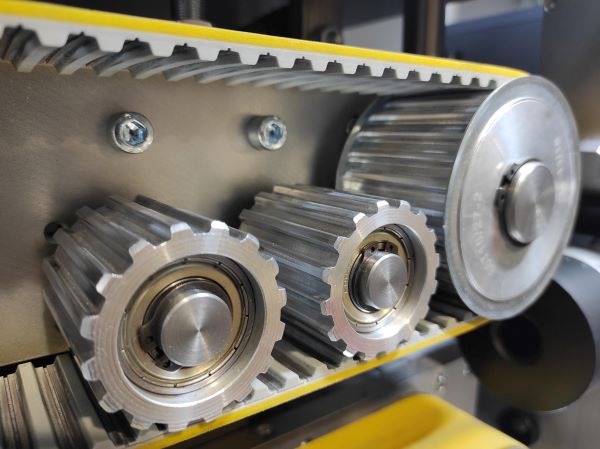

While specialized lubricants are designed to excel in specific components or equipment, a reliable general-purpose lubricant is a versatile and essential tool for any technical maintenance team. Used in a wide range of applications—from conveyor belt bearings to fan systems, milling equipment, and vehicle parts—having a dependable all-purpose lubricant can significantly enhance the performance and lifespan of machinery.

Gary Wentzel, Senior Technical Sales Representative at Lubrication Engineers (LE) South Africa, emphasizes the value of selecting the right lubricant for general applications. He explains that using a dependable lubricant across various components allows maintenance teams to focus on more complex tasks. Wentzel collaborates with mining clients who use LE’s Almatek® General Purpose Lubricant with Almasol® on their long conveyor belts, sometimes stretching over a kilometer. “With such extensive systems, maintenance teams often struggle to check the lubrication of each bearing. Using LE’s Almatek® lubricant offers more leeway for human error, ensuring the bearings’ optimal lifespan even when equipment monitoring is limited,” says Wentzel.

In mining operations, underground fans that provide essential airflow are often scattered across large areas, and technicians may overlook their importance. However, if these fans aren’t properly maintained, it can impact oxygen levels underground. In such cases, a reliable general-purpose lubricant, applied via an automated lubrication system, ensures that these critical components are well-maintained.

“Paired with an automated lubrication system, a general-use grease like Almatek® can relieve technicians from worrying about a multitude of components across complex sites, such as mines,” Wentzel adds. Automated lubrication systems, which lubricate bearings at set intervals, require minimal monitoring—technicians only need to ensure that the lubricant supply is sufficient.

Almatek® General Purpose Lubricant also finds application in farming equipment, trailer bearings, truck chassis points, and a variety of other transport and logistics operations. It is ideal for construction, marine, industrial, and other heavy-duty machinery, providing a robust solution across multiple sectors.

“Even in everyday workshop settings, this lubricant proves beneficial. It can seal mechanical components from dust or debris, forming a barrier against abrasive materials,” Wentzel notes.

The Benefits of Almasol®

What sets Almatek® apart is its versatility and long-lasting performance, thanks to the Almasol® additive. This product increases uptime, reduces maintenance costs, and lowers overall lubrication expenses. Its distinctive red color clearly indicates when fresh lubricant has pushed out the old material.

Almatek® is capable of withstanding high-impact loads, resisting washout, and staying in place without flinging. The Almasol® additive creates a protective layer on lubricated surfaces, safeguarding critical components from wear.

LE offers the product in various formats: sachets, tubes, and buckets. The sachet format allows clients to test the lubricant in small quantities, while the tube and bucket options cater to different application needs. The tube, in particular, works well with a grease gun for vehicle maintenance, making it a practical choice for a wide range of applications.